5 of the Most Pioneering Subsea Technologies in 2019

Subsea technology is fast evolving as Oil & Gas businesses realise the increasing benefits, cost efficiencies and time saving advantages that can be achieved by working in deepwater. The Offshore Technology Conference (OTC) is one of the ways that the industry celebrates innovation with its prestigious Spotlight on New Technology Awards.

Whilst the awards highlighted 15 technologies across the offshore industry, we have taken a closer look at 5 of the most pioneering subsea technologies that were recognised this year.

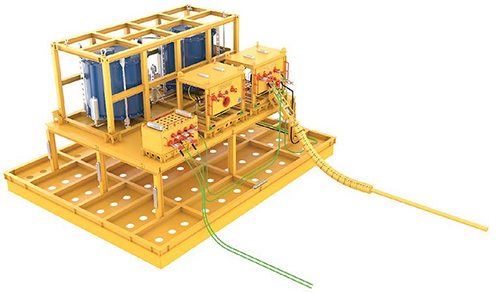

Oceaneering’s Subsea Pumping Technology

The Subsea Pumping Technology (SPT) not only reduces, but could potentially eliminate an operator’s topside footprint by transferring both chemical storage and injection capabilities to subsea.

Its many benefits include decreased costs through the removal of complex umbilicals, opening up opportunities for longer tiebacks and reduced CAPEX. This technology is another important component in the move towards automated and unmanned subsea factories which could soon become a reality.

Source – Journal of Petroleum Technology

SIEMENS’ Subsea Power Grid

Siemens’ Subsea Power Grid brings us even closer to the reality of moving floating platforms to the seafloor.

The subsea power grid consists of a transformer, a medium-voltage switchgear, and a variable-speed drive. The system can provide electricity to devices with power ratings between 1 and 15 megawatts and the umbilical that hooks it to a generation station also includes an embedded fiber-optic cable, allowing operators to control and monitor the system from a distance.

The transformational technology will help extend tiebacks and allow for flexible subsea processing.

One of the challenges this technology posed was how it could withstand the high underwater pressure. Instead of encasing all the equipment in a pressurized chamber, engineers flooded the electronics with a synthetic fluid called Midel; a biodegradable fluid inside the equipment that maintains the same pressure as the seawater, alleviating stress. The fluid also cools the device, transferring heat from equipment into the coolness of the sea.

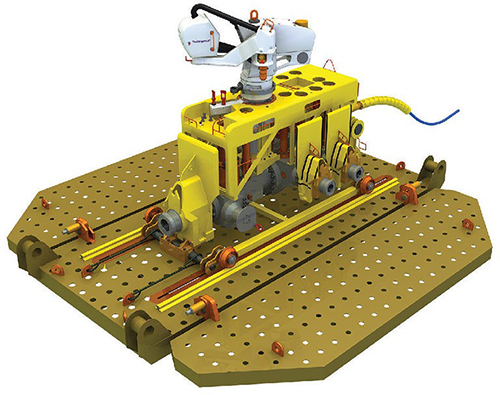

TechnipFMC’s Subsea 2.0™ In-Line Compact Robotic Manifold

The Subsea 2.0 In-Line Compact Robotic Manifold is half the size and weight of a traditional manifold, reducing both cost and delivery by up to 30%. Its production schedule can also be reduced by up to 30%, meaning faster return on investment and time to first oil.

The compact manifold has an all-electric robotic arm for value actuation, which can be operated by the topside master control station. The manifold itself can also be installed using the same vessel laying the flowline, saving the need for a purpose-built heavy lift vessel. Its hydraulic functions have been removed, resulting in a simpler manifold, produced with 10-times fewer parts which requires no structure for support or lifting. Equipment like this will help to reduce risk while decreasing engineering hours and delivery schedules.

Saipem’s Offset Installation Equipment (OIE)

The Offset Installation Equipment (OIE) from Saipem can be deployed onto an erupting subsea well, enabling capping from a safe distance from the incident and creating an end-to-end capping and containment solution suited to most subsea scenarios. It is controlled from the surface through a remotely operated vehicle (ROV) in water depths of 75 to 600 metres.

This one of a kind system is stored in Trieste, Italy, where Saipem have trained operating personnel to quickly mobilise the equipment onto a transportation vessel or by air, should an incident occur.

This technology was developed for Oil Spill Response Ltd (OSRL), and although incident prevention remains the priority, Robert Limb, CEO of OSRL, says “The Offset Installation Equipment (OIE) brings additional capabilities which complement the existing Capping Stack Systems and Containment Toolkit enabling members to prepare for, and handle, a broader range of potential subsea well control incidents on a global scale.”

OneSubsea, a Schlumberger company’s Vx Omni Subsea Multiphase Flowmeter

The Vx Omni subsea multiphase flowmeter works at 20,000 psi while expanding efficiency, accelerating lead times, and increasing reliability at the wellhead.

It provides data that is vital in understanding how an individual production well is performing, with the benefits of enhancing reservoir recovery and increasing operation safety. This piece of subsea technology allows for better decision making across the entire production cycle, by providing highly accurate multiphase flow measurement data.

There has been a 66% reduction in the Vx Omni flowmeter’s number of parts, with huge standardisation of components across pressure rating, process fluids compatibility, temperature, flow rate, and water depth.

This new tool introduces design simplification while reducing, and even eliminating, the need for surface well testing facilities and subsea test lines, which can be costly.

Subsea technologies require skilled operating personnel

The subsea industry remains positive, with many operators and EPCs investing in new technology to support their growing projects in a bid to maximise return on investment.

Simon Calvert, Client Development Manager at First Recruitment Group said, “We have seen a huge increase in the need for specialist subsea candidates over the past 2 years. I’ve noticed particular demand for experienced ROV operators as well as well intervention, installation methods & analysts and subsea instruments and controls specialists. This isn’t a surprise as many industry experts such as OGUK have predicted that the underwater market could be worth over £100 billion globally by 2035.”

As investment continues to rise specifically around new subsea technology, it shines the spotlight on the opportunities for businesses and candidates who are looking to progress a career offshore.

Subsea recruitment advice

Are you searching for skilled subsea candidates to help support your growing subsea project work? Call our Subsea specialists via +44 (0) 1925 907000 or email recruit@firstrg.com.